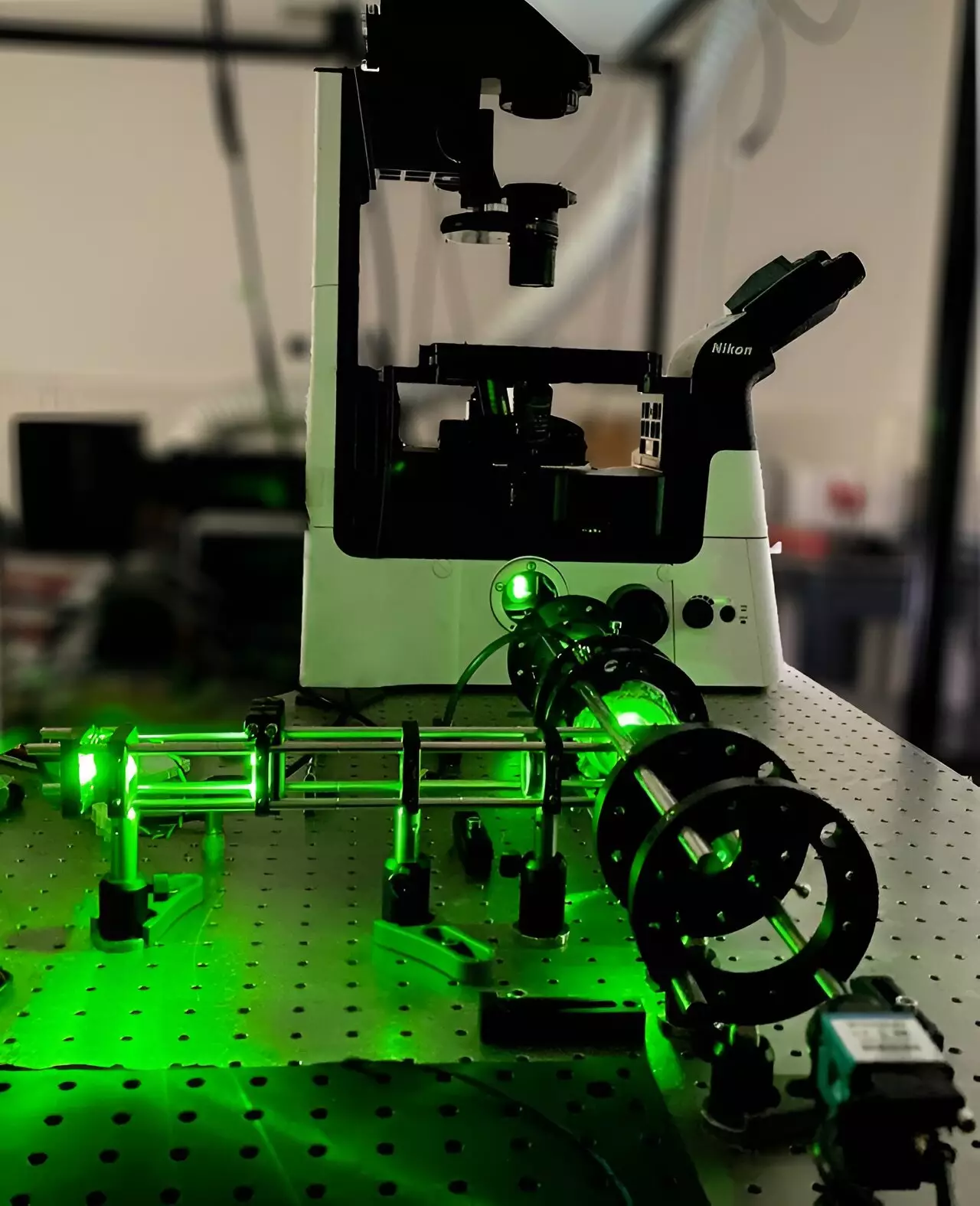

A recent breakthrough in optical profilometry technology has been achieved by a team of experts from the University of Barcelona and Sensofar Tech. This innovative technology allows for quick, accurate, and non-invasive three-dimensional imaging of study samples. Published in Nature Communications, this new system surpasses the performance of current technological systems in identifying and recognizing objects in three dimensions.

Optical profilometry is a crucial discipline used in quality control and part inspection across various industries, from 3D-printed components to coronary prostheses. Traditionally, the three-dimensional profile of micrometric objects is measured using a microscope, involving the acquisition of multiple images at different heights and planes. However, this process is inherently slow. The new technology presented in the study aims to drastically reduce the acquisition time of image collections, thereby enhancing the efficiency of optical profilometry.

The new system is capable of characterizing the three-dimensional topography of objects at the micrometer scale on relatively large samples in real-time, reaching speeds of up to 60 topographies per second. This surpasses current technological systems that are limited in speed or spatial resolution based on sample thickness. The ability of the new technology to characterize dynamic processes opens up new possibilities, such as capturing the rapid movement of small devices in 3D.

The Innovative Approach and Implementation

The implementation of the new technology involves an intelligent interrogation approach inspired by the Who’s Who game, where different planes of the sample are questioned simultaneously. This approach reduces the number of required images significantly, improving efficiency. The technique requires rapid scanning of the sample and synchronization of pulsed light using advanced tools like an ultrafast liquid lens and programmable gate array. Overcoming challenges in data acquisition rates was a critical phase in the development of this technology, successfully accomplished by the team.

Future Implications and Development

The study is part of an industrial doctorate program and supported by the European Research Council project led by Martí Duocastella. The team’s focus on designing a specific type of optical profilometer based on light pattern projection shows promise for further improvements in characterizing 3D samples with unparalleled accuracy and speed. Ongoing work aims to implement this innovative approach in various other profilometers, potentially revolutionizing the field of optical profilometry.

The innovative technology developed by the University of Barcelona and Sensofar Tech opens up new possibilities in three-dimensional imaging and optical profilometry. By enhancing speed, accuracy, and efficiency in capturing the topography of study samples, this technology has the potential to revolutionize quality control and part inspection processes across industries. With further development and implementation, this groundbreaking approach could lead to significant advancements in the field of optical profilometry.