Identifying defects in additively manufactured components has always been a challenging task in any manufacturing setting. The complexity of 3D printed components, with their intricate structures and hidden internal features, makes it difficult to spot defects with the naked eye. This poses a significant problem as defective components could lead to product failures or malfunctions down the line.

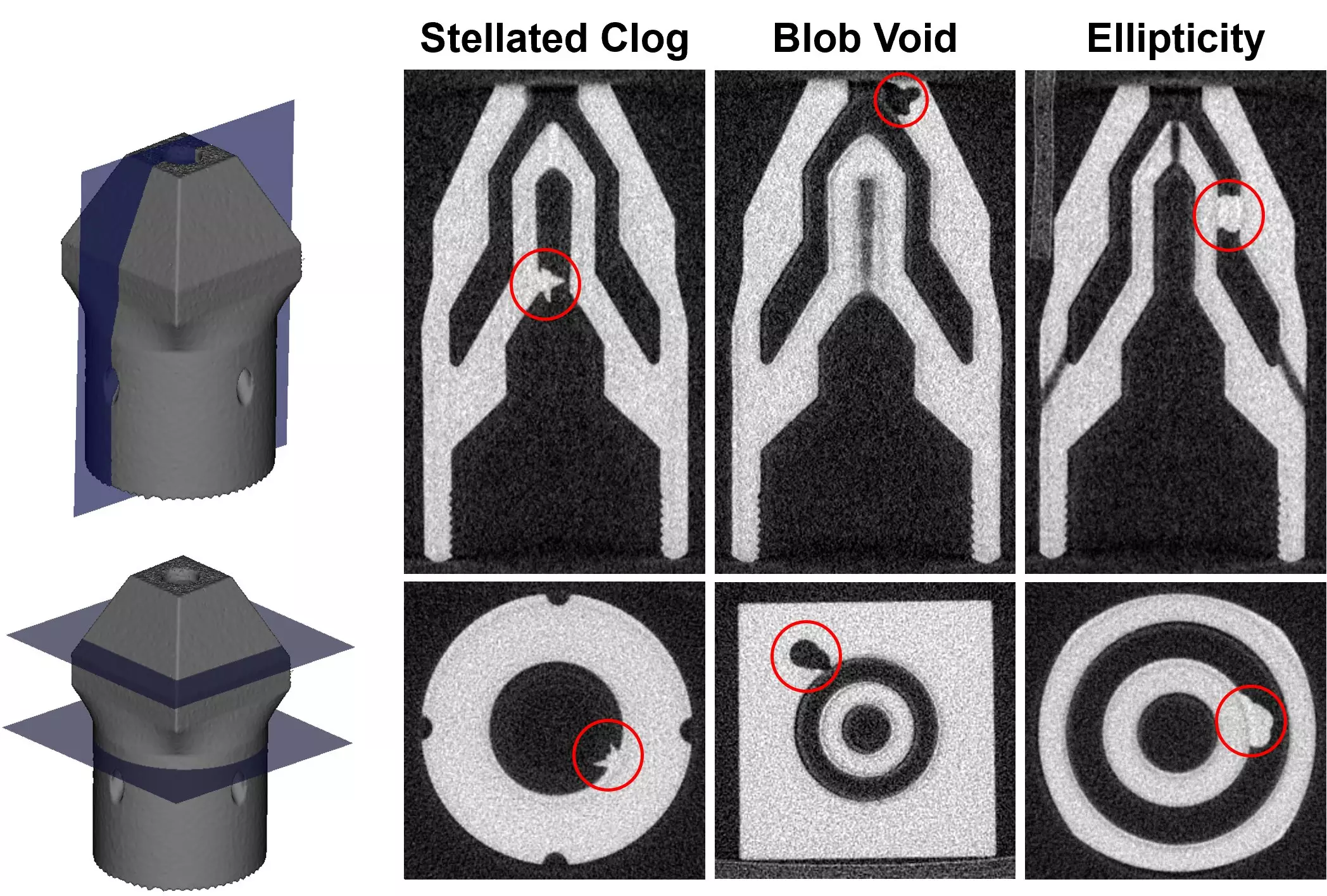

A team of researchers from the University of Illinois Urbana-Champaign has developed a groundbreaking method for detecting defects in additively manufactured components using deep machine learning. This innovative technology leverages computer simulations to create synthetic defects with varying sizes, shapes, and locations, enabling the deep learning model to train on a diverse range of potential defects. By testing the algorithm on physical parts, the researchers were able to successfully identify hundreds of defects that had not been previously detected.

The research, published in the Journal of Intelligent Manufacturing, utilized X-ray computed tomography to inspect the interior of 3D components with hidden features and defects. This technology enabled the researchers to visualize and analyze the internal structure of components that would otherwise be invisible to the naked eye. By combining deep learning with X-ray computed tomography, the team was able to accurately detect defects that had been concealed within the components.

According to William King, Professor of Mechanical Science and Engineering at the University of Illinois Urbana-Champaign, this technology addresses one of the toughest challenges in additive manufacturing. By rapidly building a machine learning model using computer simulations, defects can be identified with high precision. The ability to detect defects that were previously unseen by the computer highlights the significant impact of deep learning in improving the quality and safety of additively manufactured components.

The development of this new method for detecting defects in additively manufactured components represents a significant advancement in the field of manufacturing technology. By combining deep machine learning with X-ray computed tomography, researchers have found a powerful solution to the longstanding challenge of identifying defects in complex 3D printed components. This breakthrough has the potential to transform the way defects are detected and mitigated in additive manufacturing, paving the way for safer and more reliable products in the future.