In a groundbreaking development, a research team led by Dr. Sung Mook Choi from the Korea Institute of Materials Science has introduced a one-step electrode fabrication process for the first time in South Korea. This innovative process, as published in the journal Applied Energy, allows for the direct production of electrodes – a crucial component of anion exchange membrane water electrolysis – from raw materials to a level that is conducive to mass production.

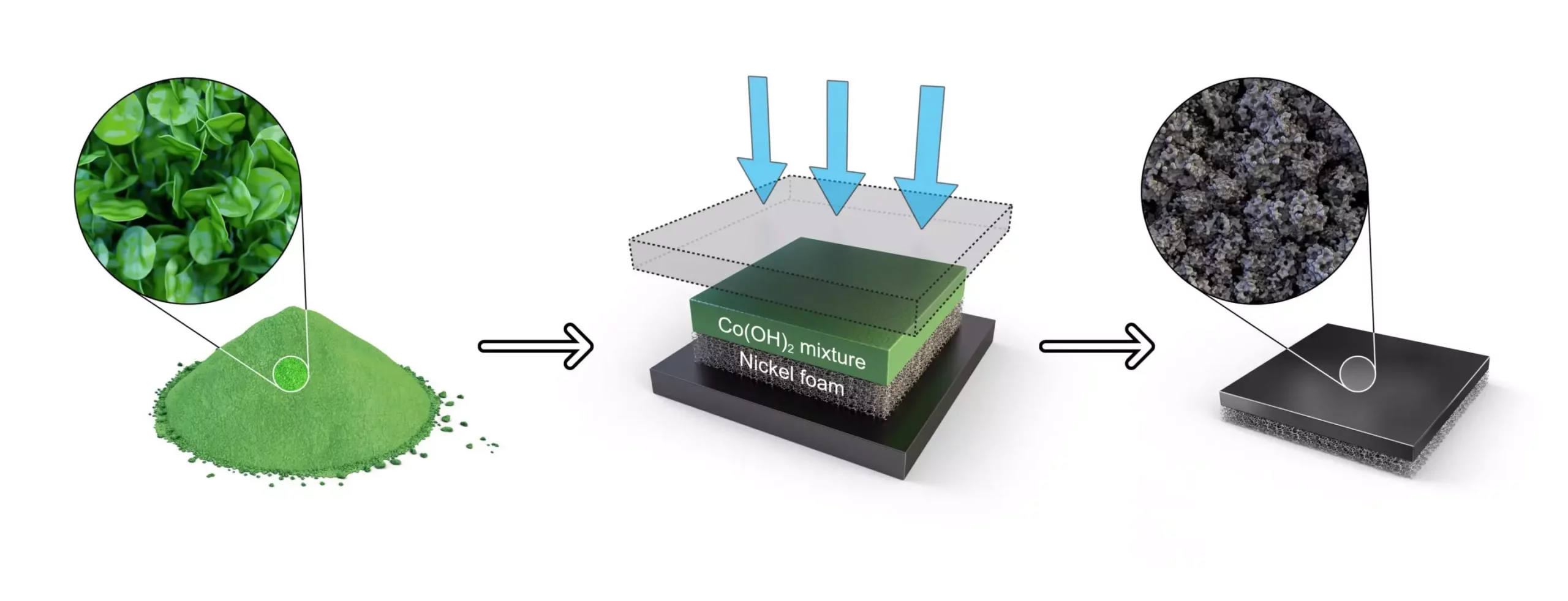

The key advancement of this new process lies in the utilization of a one-step hot-pressing method that transforms cobalt hydroxide into a cobalt oxide catalyst while simultaneously creating a highly uniform catalyst layer. By consolidating the various complex steps involved in the traditional process into a single coating step, a remarkable 60% simplification has been achieved. This streamlined approach not only simplifies the fabrication process but also results in the creation of a uniform catalyst layer, thus enhancing efficiency and durability.

To ensure the optimal performance of the one-step electrode fabrication process, the research team meticulously crafted a catalyst layer consisting of uniform oxide particles measuring just 10 nanometers in size. This was achieved through precise control of the cobalt hydroxide slurry conditions, as well as careful monitoring of temperature and pressure during the hot-pressing process. The resulting electrode was then integrated into a membrane electrode assembly (MEA) with an anion exchange membrane and a hydrogen evolution catalyst, showcasing both stability and high performance in a commercial-scale water electrolysis cell.

The potential impact of this technological breakthrough is significant, particularly in the realm of green hydrogen production from water electrolysis. Projections suggest that by 2030, global green hydrogen production could reach 11 million tons with a capacity of 69 gigawatts. In Korea, efforts are underway to develop technology for a megawatt-level anion exchange membrane water electrolysis system by 2024, with the goal of commercialization by 2030. However, despite significant progress, the domestic level of anion exchange membrane water electrolysis technology currently lags behind world-class standards, highlighting the need for increased investment and technology localization.

Through the advancement of this one-step electrode fabrication process, there is a tangible opportunity to secure a competitive edge in related technologies, localize water electrolysis technology, and establish a dominant position in overseas water electrolysis markets. Dr. Sung Mook Choi, the principal researcher behind this breakthrough, emphasized the importance of addressing key challenges related to the commercialization of anion exchange membrane water electrolysis through the development of innovative processes with high reliability.

The future of water electrolysis technology looks promising, driven by advancements such as the one-step electrode fabrication process developed by Dr. Sung Mook Choi and his research team. With continued innovation and investment, the widespread adoption of green hydrogen production methods could revolutionize the energy industry and pave the way for a more sustainable future.