In the rapidly evolving landscape of electric vehicles (EVs), the competition extends beyond mere automotive design; it delves deep into battery technology. Recently, Robin Zeng, head of Contemporary Amperex Technology Co., Limited (CATL)—the world’s largest EV battery manufacturer—sounded a stark warning about Tesla CEO Elon Musk’s ambitious plans for the 4680 cylindrical cell technology. Zeng’s evident skepticism not only raises questions about the feasibility of Tesla’s goals but also highlights the intricacies of battery manufacturing that are critical to the future of electric mobility.

The 4680 battery cells, which promise to deliver five times the energy capacity of traditional units, have been touted as a breakthrough in Tesla’s quest for efficiency. In a remarkable statement to Reuters, Zeng claimed that during a debate he had with Musk, he demonstrated key technical details that left the Tesla CEO silent, insinuating a significant knowledge gap in Musk’s understanding of battery technology. This encounter underscores a crucial point: the intricacies of battery design and production remain complex, a domain where experience and expertise can significantly impact outcomes.

Current Developments in Battery Technology

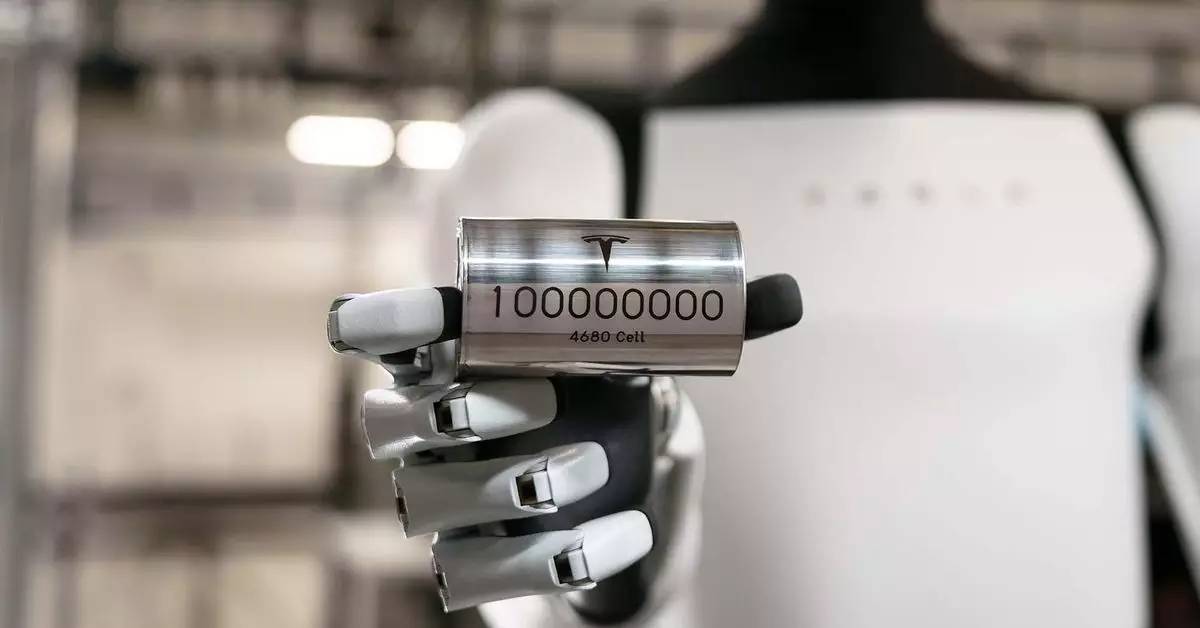

Tesla’s announcement in September that it had produced 100 million 4680 cells marked a significant milestone. However, reports indicate that Musk’s team is under pressure to address cost challenges and performance issues before year-end. Such timelines can be misleading; they reflect a trend in Musk’s leadership characterized by high expectations and aggressive deadlines. Zeng’s critiques echo the frustration felt by many industry stakeholders who have witnessed Musk’s pattern of “overpromising” timelines, especially evident in the field of Full Self-Driving technology.

Amid this tension, CATL stands out by focusing its resources on lithium iron phosphate (LFP) batteries, which, while lacking the range of Tesla’s cylindrical cells, are being integrated into a variety of electric vehicles, from the Tesla models in China to Ford’s Mustang Mach-E. This strategic choice illustrates a more pragmatic approach, leveraging the strengths of LFP batteries for mass-market applications, particularly where cost-efficiency is paramount.

The Road Ahead for Battery Technology

As the EV market continues to expand, the interplay between innovators like Tesla and established manufacturers like CATL will shape the future of transportation. Zeng’s analysis suggests that while Musk’s ideas push the boundaries of technology, they may also invite undue risks due to unfulfilled promises and the complex realities of battery production.

For Tesla, achieving the ambitious goals set for the 4680 cells is essential not just for its reputation but also for its competitive edge in the ever-growing EV market. On the other hand, CATL’s approach signals a different strategy—prioritizing reliability and scalability over game-changing innovations, aiming to sustain a robust supply chain that supports diverse automotive manufacturers.

As industry dynamics evolve, the narratives of success and failure in battery technology will undoubtedly emerge, influencing consumer choices and the broader transition to sustainable energy solutions. Ultimately, this ongoing rivalry may redefine the parameters of what is feasible, as both established and emerging players strive to power the future of mobility.