As the demand for electric vehicles and renewable energy sources intensifies, the spotlight on rare-earth elements (REEs) has never been brighter. These elements are fundamental to the production of high-performance magnets found in various green technologies like wind turbines and EVs. However, their extraction and processing have significant environmental impacts, primarily due to traditional mining methods. The need for an efficient and sustainable recycling process has thus become crucial in mitigating these concerns and ensuring a stable supply of REEs.

Researchers from Kyoto University have stepped up to meet this global challenge with a groundbreaking recycling technique known as the selective extraction–evaporation–electrolysis (SEEE) process. Under the guidance of Professor Toshiyuki Nohira and his dedicated team from the Institute of Advanced Energy, this innovative method presents a marked improvement over conventional recycling techniques. While traditional methods often involve energy-intensive and complex procedures that contribute to environmental degradation, the SEEE process is designed to address these issues by merging efficiency with sustainability.

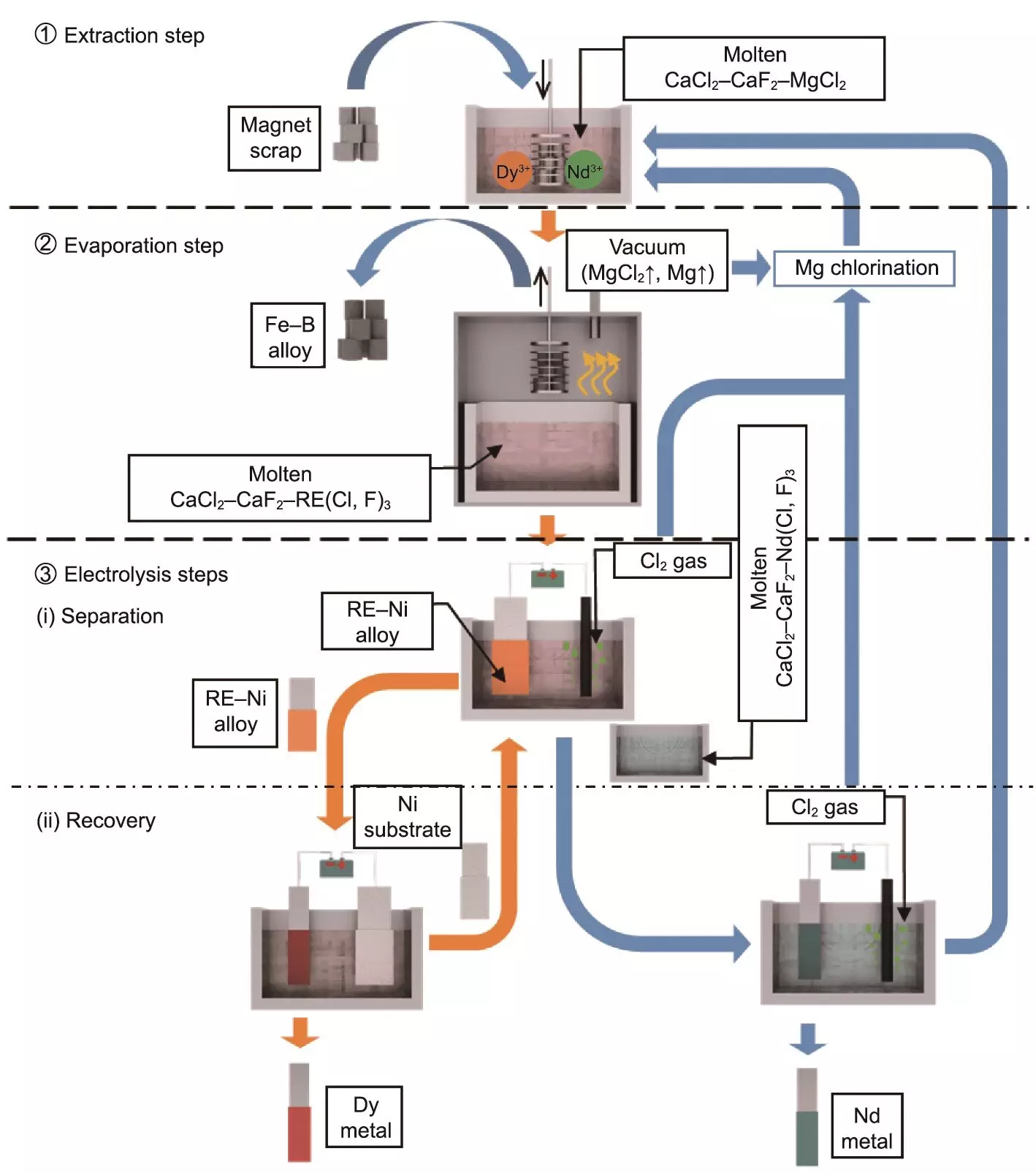

This novel process unfolds in three structured stages. First is the selective extraction, where a molten salt mixture—comprising calcium chloride (CaCl2) and magnesium chloride (MgCl2)—is utilized to extract REEs from spent magnets. Calcium fluoride (CaF2) is incorporated to minimize evaporation losses and maximize extraction efficiency. The subsequent stage, selective evaporation, concentrates these extracted materials by eliminating residual extraction agents and byproducts. The final phase, selective electrolysis, employs electrochemical methods to separate REEs based on their specific formation potentials, ultimately yielding high-purity neodymium (Nd) and dysprosium (Dy) metals.

The SEEE process showcases impressive recovery rates, achieving 96% recovery for Nd and 91% for Dy, with both metals boasting purities exceeding 90%. Such levels of efficiency dwarf those reported from existing recycling methods and suggest a transformative potential in the industry. As REEs are critical in manufacturing magnets for green technologies, the implications of this process extend far beyond mere recycling; they hold the promise of redefining the supply chain for these essential materials.

One of the remarkable aspects of the SEEE process is its versatility. The researchers indicate that the methodology could be adapted for various applications beyond just the reprocessing of Nd magnets used in energy-efficient technologies. For instance, its potential use in the reprocessing of nuclear fuels opens up avenues for broader environmental sustainability across different sectors.

This adaptability could make the SEEE process a cornerstone for future recycling technologies, not just for REEs but for a myriad of other critical materials that demand sustainable practices. As industries worldwide shift towards greener and more sustainable operational strategies, methods like SEEE stand to address the challenges of resource depletion and environmental degradation effectively.

While the study indicates considerable promise in adopting the SEEE process, the researchers also emphasize that further technical investigations are vital to seamlessly integrate this innovative method into industrial applications. As innovative recycling solutions push boundaries, the ongoing research and development in this area are paramount to maximizing the potential benefits for both industry and the environment.

The SEEE process embodies the need for advanced research to confront global environmental challenges. As countries aim for carbon neutrality, initiatives like this innovative recycling technology could pave the way for broader industry transformations geared toward ecological sustainability. By lessening reliance on newly mined REEs and emphasizing efficient recycling technologies, the SEEE process may well serve as a catalyst for a more sustainable future.

As the world grapples with pressing environmental issues tied to traditional resource extraction, the SEEE process emerges as a beacon of hope. This elevated recycling methodology not only aligns with global sustainability goals but sets the stage for innovations that could revolutionize the recycling of rare-earth elements and further enhance the transition toward greener technologies.