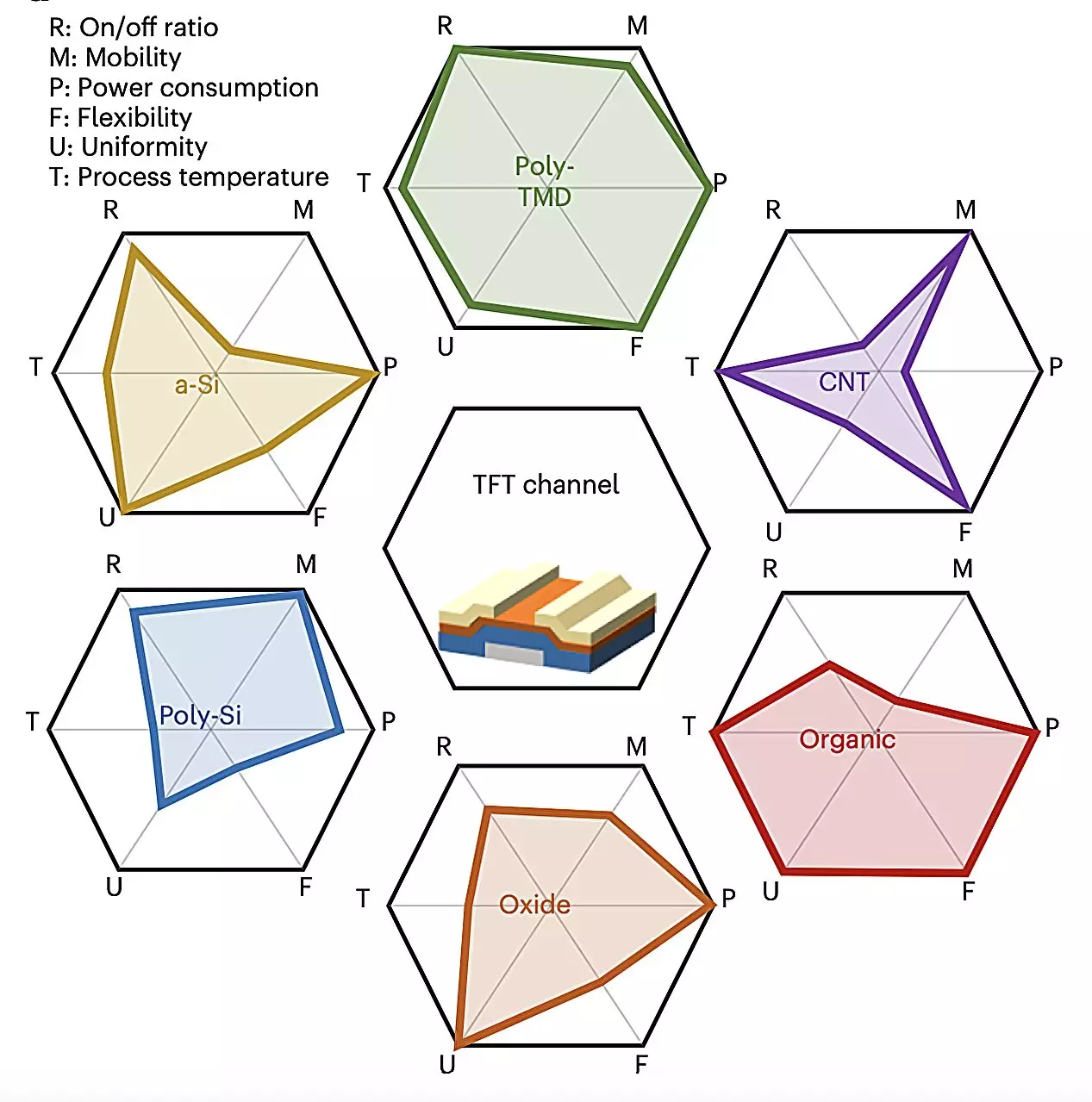

In the ever-evolving field of electronics engineering, researchers are constantly seeking to develop innovative transistors that can be scaled down to smaller sizes. Traditional silicon-based field effect transistors (FETs) have their limitations, which has led to the exploration of alternative materials with higher electron mobility. Transition metal dichalcogenides (TMDs) have emerged as one of the most promising materials for creating scalable FETs due to their small length and good carrier mobility.

Among the TMDs, molybdenum disulfide (MoS2) has garnered significant attention. This compound, consisting of molybdenum and sulfide atoms in a 1:2 ratio, has shown great potential for the development of next-generation transistors. A recent study by researchers at Samsung Advanced Institute of Technology (SAIT) and Seoul National University showcased the integration of MoS2 transistors on a 200 mm wafer, demonstrating the scalability of these transistors and their potential for powering smaller and more flexible devices.

The research team employed a unique approach to fabricate large-scale arrays of MoS2 FETs using metal-organic chemical vapor deposition (MOCVD). By eliminating the Schottky barrier at the interface between the MoS2 material and metal, the team was able to enhance the carrier mobility of the FETs. The fabrication strategy demonstrated by the researchers is not only compatible with existing electronics manufacturing processes but also boasts an impressive yield of over 99.9%.

The MoS2 FETs designed and fabricated by the research team exhibited exceptional performance in initial tests. They outperformed previously introduced FETs based on MoS2 in terms of field-effect mobility, contact resistance, and on-current densities. This remarkable performance was attributed to the innovative fabrication steps introduced by the researchers, which eliminated the Schottky barrier and reduced contact resistance at the MoS2/metal interface.

The integration of FETs on a 200 mm wafer revealed uniformity across the devices, with only slight variations observed. This not only highlights the potential for large-scale commercialization but also underscores the importance of reliable fabrication processes. The research conducted by the team could serve as a catalyst for other researchers to explore similar FET designs and fabrication techniques, ultimately accelerating the development and widespread adoption of high-performance transistors based on MoS2.

The advancements made in the field of electronics engineering, particularly in the realm of MoS2 transistors, hold great promise for the future. The scalability, enhanced carrier mobility, and compatibility with existing manufacturing processes make MoS2 a frontrunner in the quest for more efficient and compact electronic devices. By building on the foundation laid by the researchers at SAIT and Seoul National University, the electronics industry stands poised to usher in a new era of technological innovation.