In our energy-constrained world, optimizing the efficiency of the devices we use every day is becoming increasingly important. Among the unsung heroes in our quest for sustainable energy consumption are small electric motors, which power an array of household appliances, tools, and even vehicles. While each motor might draw a modest amount of energy, the cumulative effect of these devices can be significant. Recent innovations, particularly those spearheaded by a dedicated research team at Graz University of Technology, reveal untapped potential in the realm of brushless electric motors, particularly in their application in pumps and fans.

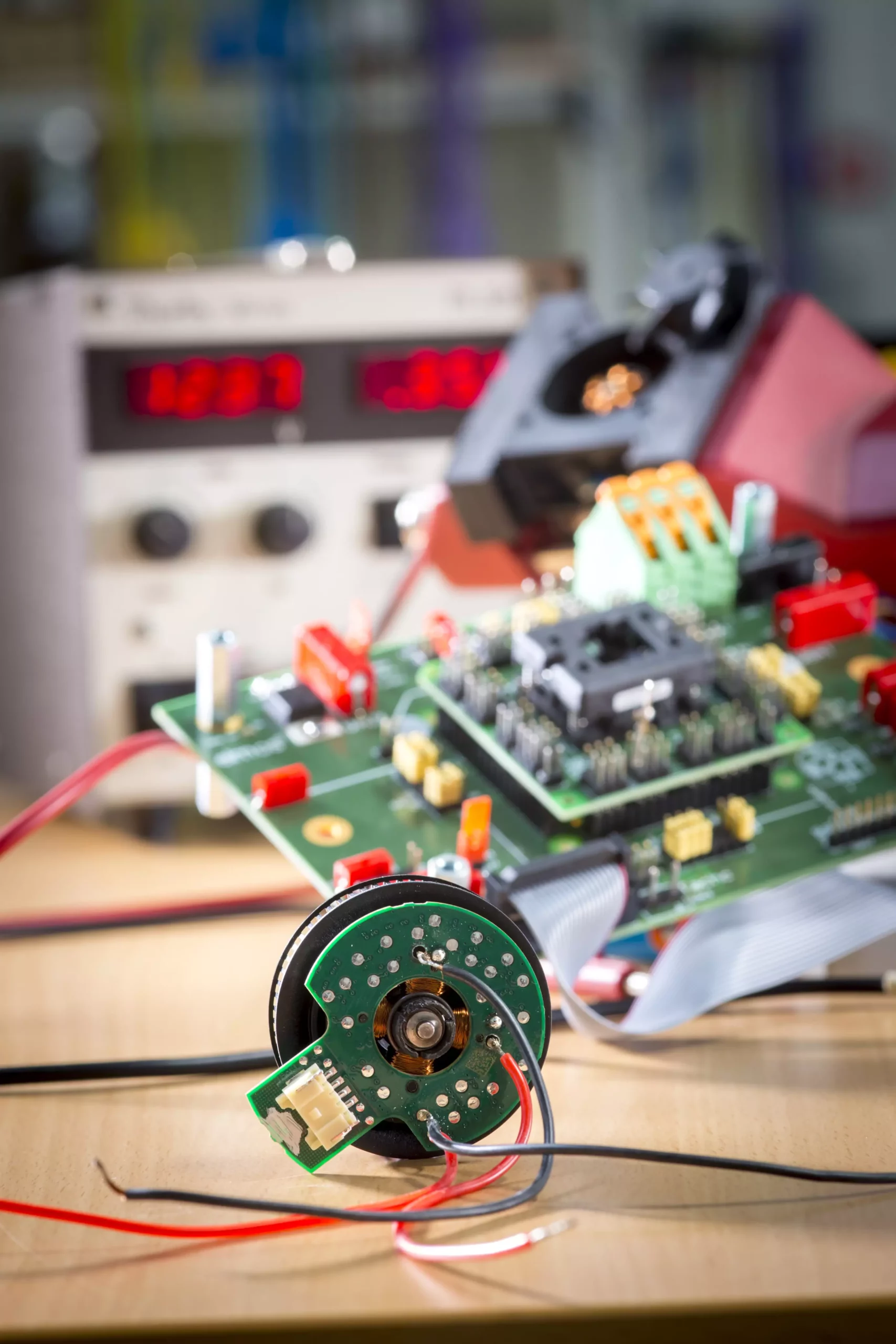

Led by Annette Mütze, the Electric Drives and Power Electronic Systems Institute at TU Graz has made notable progress in enhancing the efficiency of brushless integrated drives. These advancements stem from a combination of innovative design strategies, modified control technologies, and new manufacturing techniques. Collectively, these changes not only conserve energy but also result in quieter and lighter motors, which can significantly improve user experience across various applications.

Traditionally, claw pole motors are implemented in vehicle lighting systems. Mütze’s team effectively brought these motors into the limelight for small drive applications in light of their enhanced functionality. The traditional challenges associated with cogging torque, which generates undesired vibrations, have been mitigated by slightly altering the design of the motor’s claws through skewing and slotting techniques. This innovation not only smooths out the operation of the motor by reducing vibrations, but it also leads to a remarkable noise reduction by 70%, creating a much quieter workspace or living environment.

Perhaps one of the most fundamental shifts in motor efficiency formulated by Mütze’s team lies in the rethinking of current regulation methodologies. Traditionally, pulse width modulation (PWM) techniques would govern the electricity supplied to motors, requiring numerous switching operations to achieve the desired current flow. While effective, this method introduces additional energy consumption due to switching losses.

Mütze’s innovative approach redefines this norm by utilizing a simpler on-off switching mechanism, significantly lowering the switching operations needed to regulate power. This breakthrough drastically enhances the overall efficiency of the motors, particularly at lower currents, providing a more viable and energy-efficient alternative to conventional PWM-controlled motors. Not only does this lead to a reduction in energy consumption, but it also allows for optimization in the design of associated circuit boards—halving the number of capacitors needed, thus curbing manufacturing costs.

As the world moves toward increasingly automated production lines, the incorporation of printed circuit board (PCB) technology into motor design has set a new standard. By using PCB technology to create the essential windings responsible for generating magnetic fields, Mütze’s team has significantly streamlined the manufacturing process. The implementation of 3D-printed ferrite cores is a key aspect of this innovation, improving the magnetic flux guidance essential for motor performance while utilizing cost-effective materials that don’t compromise on quality.

This transition to PCB motors with ferrite cores not only exemplifies ingenuity in material use but also reflects the industry’s shift toward sustainable manufacturing practices. The efficiency gained from these motors, combined with their potential for mass production through automation, promises significant benefits for consumers and manufacturers alike.

The innovative advancements in brushless electric motors celebrated by Mütze’s team are not simply incremental upgrades; they mark a paradigm shift in energy efficiency in everyday appliances. By addressing design flaws, refining control methodologies, and embracing new manufacturing technologies, these innovations hold the potential for widespread application, from household gadgets to automotive components.

As we continue to confront the challenges posed by energy consumption and environmental sustainability, embracing such technologies is vital. While small electric motors may not seem like major energy consumers at first glance, their cumulative effect necessitates a proactive approach to efficiency. The pioneering efforts of researchers like Annette Mütze at TU Graz serve as a crucial reminder that even minor improvements in technology can yield monumental benefits for energy conservation and environmental stewardship in our everyday lives.